Turn-Key Solutions

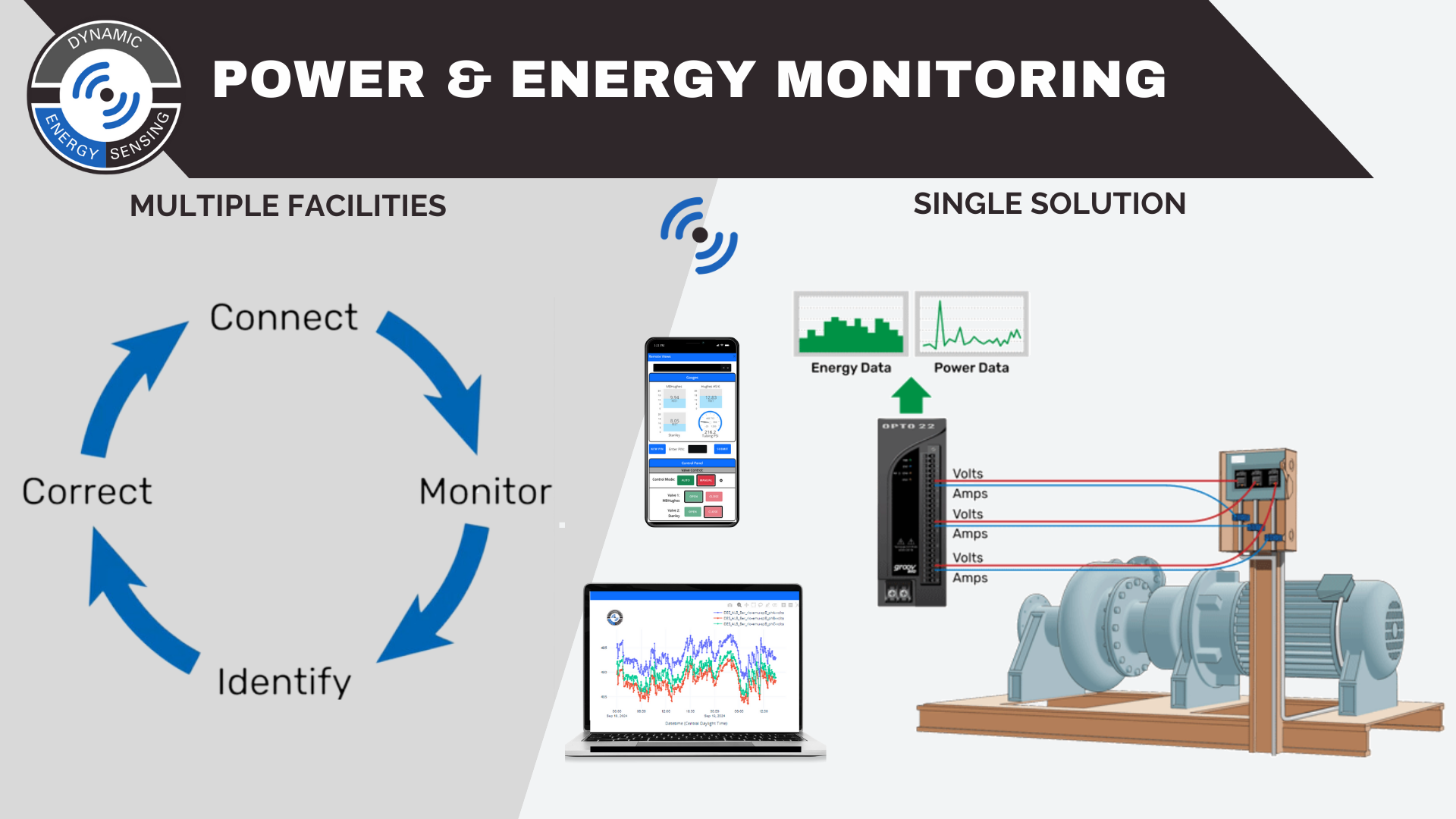

Understanding that implementing remote monitoring, control, and automation systems can appear daunting, we at Dynamic Energy Sensing have made it our mission to offer the most streamlined and cost-effective solutions available to industrial operators. Our goal is to empower you with highly reliable and actionable data you need to enhance safety, minimize downtime, and optimize production. We deliver comprehensive, turn-key SCADA systems that require no programming on your part. Our seasoned experts handle all technical details, ensuring the solutions we deliver fit your operations seamlessly. With all necessary hardware included and an installation process designed to be completed in minutes, not hours, we offer an easy path to swiftly and effortlessly start monitoring and controlling your operation's productivity and efficiency.

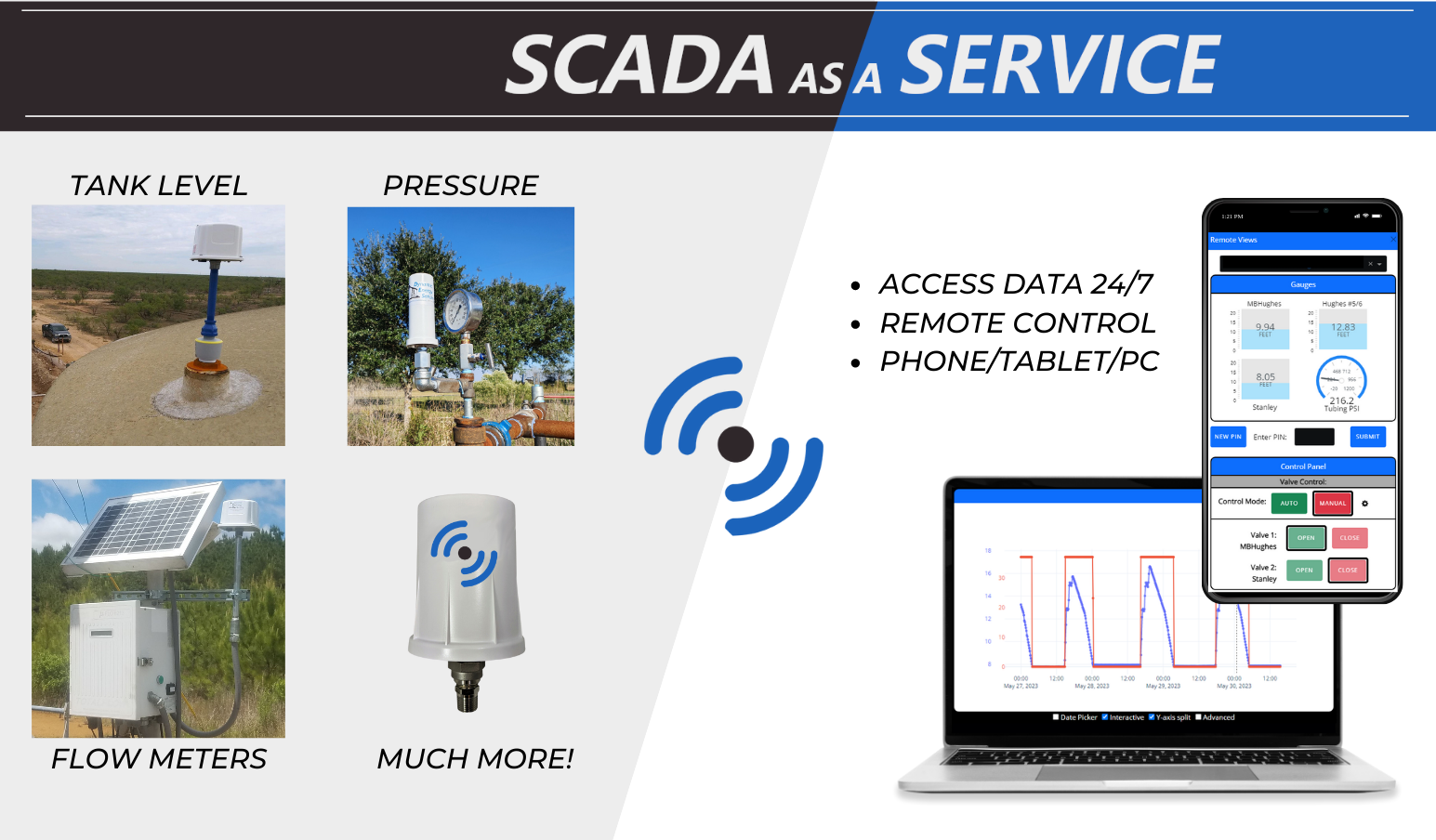

Wireless Sensors

Whether your operation involves monitoring a single asset or automating an entire field, we have wireless sensor solutions tailored to realize your goals. As a comprehensive provider, we offer wireless sensors capable of monitoring everything from tank levels, pressures, flow rates, and temperatures to motor voltage and current. Beyond monitoring, our innovative wireless technology extends to the remote control and automation of valves, electric motors, and well-shut-in systems. By harnessing the power of wireless technology, we aim to minimize installation complexity, maximize flexibility, and enhance your operational efficiency.

Simple Installation

Our wireless sensor solutions are designed to be user-friendly, with most products capable of self-installation within minutes. We provide clear, step-by-step instructions that guide you through the installation process, ensuring a smooth and hassle-free setup. However, if you'd prefer a hands-off approach, our professional installation service is available to ensure your systems are up and running optimally.

Reliable Data 24/7

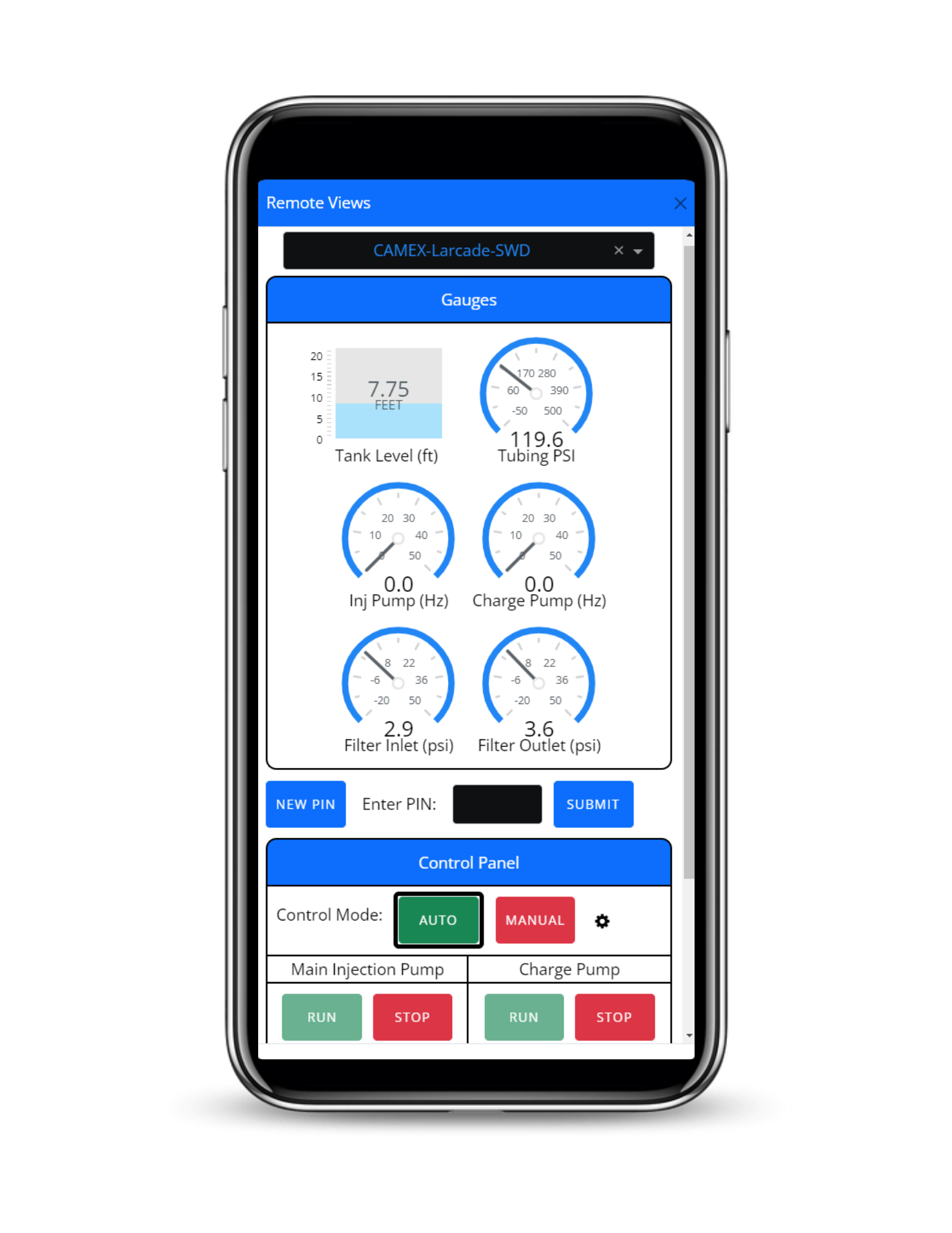

Imagine the power of shifting from daily checks to real-time, 24/7 monitoring and control. With our systems, this power is at your fingertips. Our intuitive web portal offers a wealth of data, providing an in-depth, round-the-clock view of your operation. You don't need a PhD to navigate it—our platform is designed for ease of use. Real-time data with up to 5-second sampling, immediate text/email alerts, daily reports, historical trending - all this and more is available anytime, anywhere, and on any device. With Dynamic Energy Sensing, you're not just monitoring, you're mastering your operation.

Applications

Oil & Gas Production

With real-time remote monitoring and control, our systems offer oil and gas operators the ability to optimize production, mitigate risks, and streamline operations. Our solutions can monitor crucial metrics such as tank levels, pressures, flow rates, and motor voltage/current, while also offering control and automation capabilities for valves, electric motors, and well-shut-in systems. These features help maximize production, minimize downtime, and enhance safety, providing operators with an affordable, reliable tool to optimize their oil and gas production operations.

Saltwater Disposal

If you are familiar with the costs for associated with accidental injection of sludge into a saltwater disposal well, you will be glad to hear that you can get started today with a remote monitoring system for a fraction of the cost of remediation. Does someone have to go on-site to manually start and stop your injection pumps? Contact us today to find out how we can automate your pump controls and help you avoid unecessary site visits.

Pipeline Monitoring

Whether you're looking to detect leaks on a remote oil pipeline or receive real-time text/email alerts when a filter needs replacing at a wastewater facility, our systems provide the comprehensive monitoring solution you need. We offer capabilities for tracking crucial operational metrics and enabling proactive maintenance, ensuring the safe and efficient functioning of your pipeline systems. With our solutions, you can stay one step ahead of potential issues, ensuring uninterrupted operations, and maximized safety.

Technological Advantages

- Wireless sensors with 5 year plus battery life

- No cabling = simple installation

- Half mile range to base station

- Multiple asset monitoring from base station

- Solar powered base station (cellular or satellite)

- Eliminates the need for chart recorders

- Cloud based

- Ability to integrate disparate and legacy systems into the Dynamic Energy Sensing Monitoring System

- Ability to integrate with ERP systems

| Features | Traditional Safety System |

DES Safety System |

|---|---|---|

| PRESSURE MONITORING: | Pressure Switch | Wireless Pressure |

| Shut-in well | 🗙 | ✅ |

| Adjust pressure trip level remotely | 🗙 | ✅ |

| Monitor real-time well pressures | 🗙 | ✅ |

| Inspect well pressure trends | 🗙 | ✅ |

| TANK LEVEL MONITORING: | Pressure Switch | Wireless Radar Level |

| Shut-in well based on tank level | ✅ | ✅ |

| Adjust tank level trip remotely | 🗙 | ✅ |

| Monitor actual level of tank in real-time | 🗙 | ✅ |

| Inspect well tank level trends | 🗙 | ✅ |

| ADDITIONAL FEATURES: | ||

| Know if safety system is offline | 🗙 | ✅ |

| Custom callouts sent to phone/email | 🗙 | ✅ |

| Monitor existing sensors/PLCs/RTUs | 🗙 | ✅ |

| Modify system without hiring SCADA tech | 🗙 | ✅ |

Next Steps...

Are you ready to enter the age of the Digital Oilfield?